In 1958 C & G opened its first readymixed depot at Newark, Notts. The firm was owned by Tim Clancy and Frank Gilman, who were already partners in the building and civil engineering firm Stamford Construction Ltd. The two Bedford truck mixers were fitted with horizontal discharge Rapier mixers of 2.5 cubic yards capacity.

New depots rapidly followed at Stamford and Grantham, then Peterborough and King's Lynn. Meantime Leyland Comets had joined the fleet, still with horizontal mixers. These proved fast and reliable, but their brakes were poor.

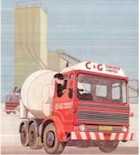

In 1962 new style "high discharge" mixers enabled skips to be filled and concrete to be more easily spread with less shovelling. These first joined the C & G fleet in 1962 on ERF 4-wheelers which proved underpowered and very slow. ERF 6 and 8-wheelers followed, carrying 6 and 8 cubic yards of concrete, and were better machines. These set the scene for the modern truck mixer recognisable today.

Stamford By-Pass, Alconbury By-Pass, 18 miles of M1 motorway between Leicester and the Trent River were some major civil engineering projects built with C & G concrete in those early days. Meanwhile, countless small jobs were completed such as house foundations, garage drives and agricultural buildings, all to the same standards as the big contracts.

An AEC Marshall and a Leyland Retriever 6-wheeled chassis were taken into the fleet for trials, but for different reasons, proved less than ideal. In 1964 Construction & Use Regulations were revised, permitting increased payloads on new trucks. In 1968 plating and annual testing arrived, with the requirement for improvements to braking systems on existing vehicles.

By 1964, a special 6-wheeler chassis had been developed by Leyland for truck mixer duties, the Super Comet 20SC, which permitted a legal payload of 6 cubic yards in a reliable package. They were followed by the similar Leyland Bear which had a gross weight of 22 tonnes thus permitting 5 cubic metres of concrete to be carried; metrication having occurred on 1st January 1971.

C & G had been an early member of the British Ready Mixed Concrete Association (BRMCA) and in 1967 had been one of the originators of its Authorisation Scheme. This industry wide scheme provided assurance that when one cubic yard or metre was ordered, our customer actually got the measured one cubic yard or metre. It gave assurance that with nominal mixes such as 1:3:6 and 1:2:4 our customer actually got the full amount of cement they were entitled to from that product description. It introduced the concept of routine statistical production control testing, replacing the old way by which customers were responsible for all product tests.

In the 1970's, C & G re-built depots acquired from Redland at Lincoln, Sleaford and Skegness; from Hennebique Concrete at Boston and Woodhall Spa; and from Amey Premix at Market Deeping. In 1974 new depots were built at Gedney and Market Rasen to give good customer service over a wide area.

In 1973 C & G ordered a new fleet of Leyland Bison trucks, these operated at 24 tonnes and carried 6 cubic metres of concrete.

Powered by the Leyland fixed head 0.500 engine of 8.2 litres, these were all fitted at Stamford with Allison automatic transmissions, which gave safer driver control, particularly reversing on delivery sites. Our livery changed from maroon cab and light battleship grey mixer to the current white and red scheme.

In 1980, an additional depot at Downham Market was acquired.

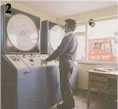

In 1981 C & G went live with its Central Dispatch system, the UK's first fully integrated company-wide Central Dispatch system. Its continued development puts us at the vanguard of technological change in our industry. Our systems integrate sales, order taking, auto-batching and recording, dispatching, materials re-supply, technical control and accounting functions. These systems allow C & G to maximise efficiency and give better customer service. At this time it was feared that our lack of in-house aggregate supplies might lead our various existing suppliers to apply a commercial squeeze, in an era of consolidation and amalgamation by our major national competitors. As a defensive move C & G then purchased gravel bearing land to ensure long term security of supply.

Truck mixers and Central Dispatch are linked |  Loading at the depot |  Cube testing at C & G's laboratory |  On-site delivery |

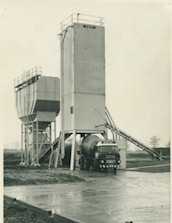

Weigh-Batching plant |  View of vehicle workshop |

By the early 1980s it was clear that the industry led BRMCA Authorisation Scheme should be replaced by a stronger independently chaired quality scheme, with equal representation from industry and customer interests, and with stronger teeth for the enforcement of standards. So was born in May 1984 the Quality Scheme for Ready Mixed Concrete. By 1988, QSRMC had been accredited by Government to provide certification of producers' quality management systems, and of their product conformity. The chief executive of C & G was a founder member of QSRMC's Governing Board.

By 1985 it was clear that our major competitors had vacated a section of the market to small trucks owned by independent producers who operated in the main without the assurance provided by the Quality Scheme for Ready Mixed Concrete. So we set up our Mini Load Concrete operation to provide quality assured products in this marketplace.

At the end of 1986 the first generation of our Leyland Constructor truck mixers joined the fleet. Like the Bisons they gradually replaced, their sweet running 8.25 litre engines were fitted with Allison automatic transmissions; and super single rear tyres were standard to avoid bringing site mud onto the highway.

Initially operating at 24.38 tonnes, they were up-rated to 25.41 tonnes as legislation changed. Later generation constructors operate at 26 tonnes, which permitted the installation of a more powerful but heavier engine of 11.6 litres.

It may be noted that for trucks, the legal speed limit on single carriageway roads remains set at 40 miles per hour. At least the law requiring a man on foot carrying a red flag to precede a motor vehicle no longer exists!

In both the 1980's and again in the 1990's senior C & G executives have served as Chairmen of BRMCA, the UK national trade association for the ready mixed industry. From 1997 to 2000, C & G 's Chairman served as President of the European Ready Mixed Concrete Organisation (ERMCO), having represented the UK industry at the European level since the retirement from that task in 1989 of RMC Group's John Camden.

By 1989, some C & G concrete was being made from our own Norton Bottoms aggregates. These materials are quarried from the nationally renowned Trent Valley geological deposit, and are of the highest quality. Planning restrictions prohibit sales of these materials to the retail market, only wholesale outlets can be served, and then only by our own transport. Over time, our Norton Bottoms pit is expected to play an increasing role as a major source of Trent Valley aggregates in the East Midlands.

In August 1989, the increasing need for quality mortar made it possible for C & G to introduce their Trowel Ready Mortar, which is now available throughout our trading territory, together with Screeds and Plaster.

In 1992, the benefits of conveyored concrete became available to C & G's customers.

In 1998 the Caistor based quarrying firm of J W Hurdiss Ltd was acquired, to extend operations to the Humber River, and to widen our product range into all types of quarry materials, supplied to all classes of customer.

In 2004, we changed our trading style to C & G Construction Solutions and brought J W Hurdiss fully into the family as C & G Quarried Products. Also in 2004, Rouse Readimix came into the C & G family, extending our concrete, screed and mortar availability to Humberside.